Find us at the EST Strategic Partner Conference

Find us at the #EST Strategic Partner conference this week for exciting new product information. Ben Lombardo and Aaron Skiles will be showcasing our new UL 864 Listed prefabricated terminal cabinets along with some of our other innovative solutions. Please come by, say hi and drop off a card to win a #YETI Hopper Cooler.

UL864 Listed Terminal Cabinets Shipped Out!

Kirkland wants to help you be more successful on your projects! Our customers are seeing the value these UL864 listed prefabricated damper and fan terminal cabinets bring to their smoke control projects. Savings are being realized from management through installation in time and money.

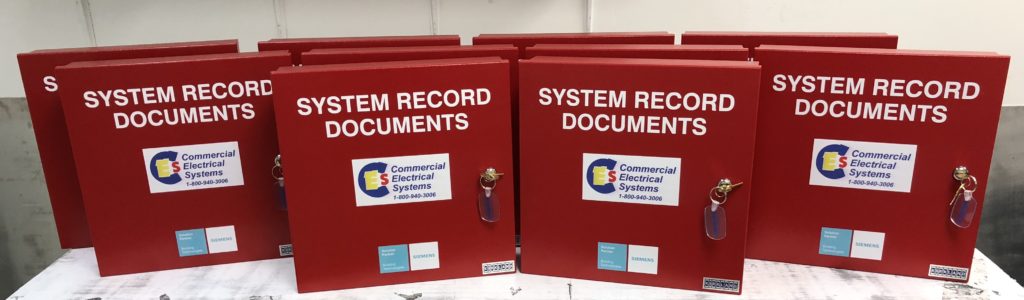

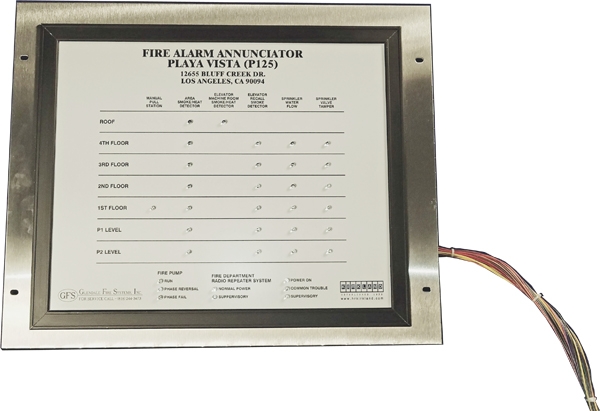

Helping Our Customers’ Customers

Helping our customers get out in front of their customers with these customized SRD’s. We can design your products to help you get more exposure in the Fire Alarm market.

Have a Happy Labor Day!

Happy Labor Day!

From all of us at H.R. Kirkland

Did you know?

100% of H.R. Kirkland products satisfy “Buy America” requirements.

Using the latest technologies, the H.R. Kirkland Company, Inc. manufactures the highest quality Fire Alarm Annunciators (Graphic, Directory, Backlighted, Exterior), Custom Control Panels, Jail Panels, Smoke Control Panels and Graphic Maps. Kirkland Interior and Exterior annunciators are UL and CSFM listed, and the Smoke Panels can be UUKL listed.

The Kirkland commitment to quality and service cannot be matched. We are dedicated to providing the very highest quality product, quick turnaround schedules, and ease in making future modifications.

WE ARE THE ONE YOU CAN DEPEND ON SINCE 1930.

The Grand Design: BEC Rises to the Challenge for the Wilshire Grand Fire Alarm System

Installing a fire alarm system in the tallest building west of the Mississippi River is no easy task. However, Rick Taylor and his team from Building Electronic Controls Inc. (BEC), Glendora, Calif., were up to the task.

In 1995, BEC was formed as a specialty electrical contractor and an Edwards engineered systems distributor. Today, it provides fire detection systems for commercial buildings, and it is a leading fire, life safety, security and network infrastructure company in the greater Los Angeles area. The Wilshire Grand is BEC’s largest single property.

Owner Korean Airlines and architect AC Martin wanted to break the tradition in Los Angeles for flat-top buildings, even though an emergency helicopter landing pad is required to obtain Los Angeles Fire Department (LAFD) approval. While the Wilshire Grand has a tactical landing pad, it does not define the shape feature of the top of the building. To build the building without the approved emergency landing pad, the owner and the architect submitted a comprehensive modification request to the LAFD, creating special conditions that affected the life-safety system.

AC Martin agreed to provide an enhanced design approach, including full-area smoke detector coverage and a designated firefighter’s emergency elevator with a dedicated camera-viewing system in each lobby.

The building met all of the LAFD requirements. The company designed, furnished and installed the fire alarm, emergency voice evacuation and smoke control systems. All three systems integrated into one Edwards EST3 platform.

BEC worked as a subcontractor to San Jose, Calif.-based Rosendin Electric, which furnished all raceways. BEC installed the wire, making all terminations and performing all programming.

At the time of the temporary certificate of occupancy (TCO), the integrated life safety system had more than 9,000 active addressable points with 3,500 smoke detectors to support the smoke control system, automatic sprinkler system monitoring, manual pull stations, and firefighters’ two-way communication, plus other emergency systems monitoring.

By the end of construction, the building had more than 5,000 area smoke detectors with several large areas protected by aspirating-type smoke detection (ASD) systems. ASD systems, rather than linear projected beam-type smoke detectors, fully protect large, high, open atrium areas. Elevator shafts that required smoke detection, and did not have access at the top of the shafts, have small single-unit ASD systems. Because no elevator machine room or shafts have automatic sprinkler protection, the fire alarm system design did not include elevator shunt trip operations.

A collaborative design effort between BEC and mechanical contractor ACCO created the smoke control system. They based this design on a rational analysis prepared by Exponent.

The smoke-control system has a unique design that provides five separate systems with different design objectives. The restaurant, lounge and club areas serving the top five floors, which share an open atrium, use one design. The hotel floors and office levels each have separate designs. Levels 1–7 share a common open atrium with an exhaust system. Finally, the five parking levels have a defined air change design separated into two zones by rolldown doors at mid-level.

One common element of the smoke control system design incorporates the main pressurized stairs that span the total height of the building.

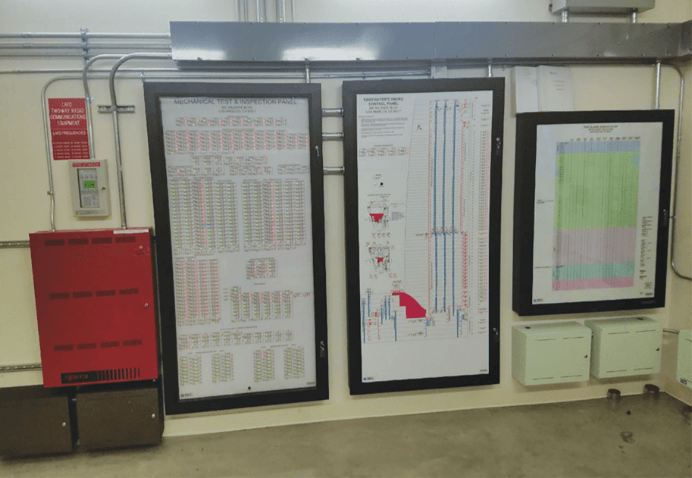

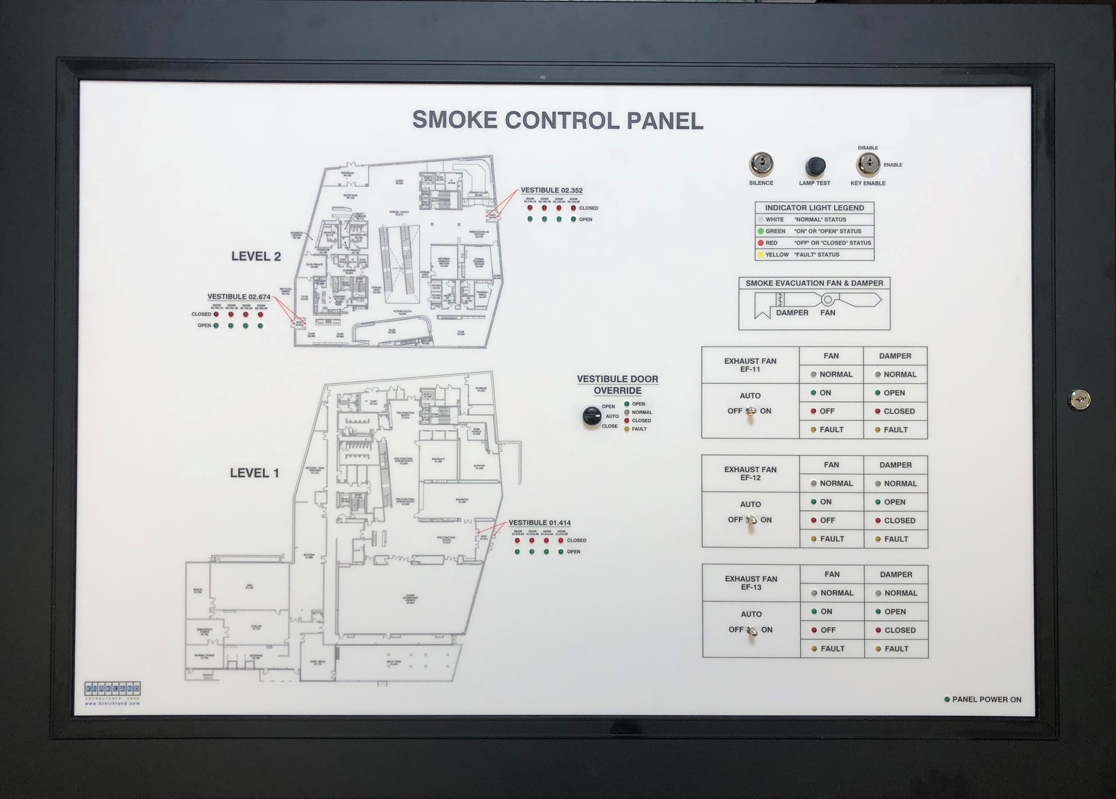

In addition to a smoke-control graphical display (SCGP), the LAFD and the Los Angeles Department of Building and Safety (LADBS) required the installation of a unique, separate mechanical test panel (MTP) with per-zone activation switches and LED indicators. This panel displays every individual element of the smoke control system with individual manual activation switches to assist in initial testing, automatic weekly testing, annual inspections, and fire department control operations during a fire in the building. Designers were challenged to fit all of this information into individual SCGP and MTP panels given the height of the building and the large number of fans and dampers. BEC designed these panels in collaboration with H.R. Kirkland.

Read the FULL article online here.

More information on Building Electronic Controls Inc. (BEC) here.

Peak Season Deliveries in just 3 – 5 Days!

“I received my graphic annunciator and I just wanted to say WOW!” –Simplex Distributor

Delivery schedules got you down?

During this peak construction season, Kirkland still maintains our superb delivery schedule, beating out the competition and exceeding our customers’ expectations. We’re the one you can depend on and pride ourselves with providing the fastest delivery times in the industry. A typical UL/UUKL certified panel turnaround time is just 3 – 5 business days after proof approval! We won’t let you down.

Happy [early] Independence Day!

With most businesses closed on July 4, we wanted to wish you an early Happy Independence Day.

Are you experiencing delivery delays because of the holiday? With H.R. Kirkland, you’ll receive an outstanding product with one of the quickest turnarounds in the industry. We aim to provide drawings for approval within 2 – 3 business days and, once approved, have the in-house equipment to build UL / UUKL certified standard panels as quick as 3 – 5 business days.

The Kirkland commitment to quality and service cannot be matched. We are dedicated to providing the very highest quality product, quick turnaround schedules, and ease in making future modifications.

Outstanding Deliveries since 1930.

We won’t let you down.

WINNER: Mike McDade from COSCO Fire Protection!

We like to think ALL our customers are WINNERS! As part of our Customer Appreciation Contest, we randomly selected Mike McDade of COSCO Fire Protection to win a Yeti-style Kirkland logo tumbler for taking our survey and “liking” us on Facebook. Thanks Mike!

Thanks to everyone who took the time to provide feedback on our survey. You’re the reason we love our job 🙂 You can always reach our customer service department at (800) 247-2303 with comments and questions. We appreciate your feedback and your business is important to us. Be sure to continue to follow our feeds and connect with us on Facebook and Linkedin.

FACEBOOK LINK: https://www.facebook.com/hrkannunciators

LINKEDIN LINK: https://www.linkedin.com/company/hrkirkland/

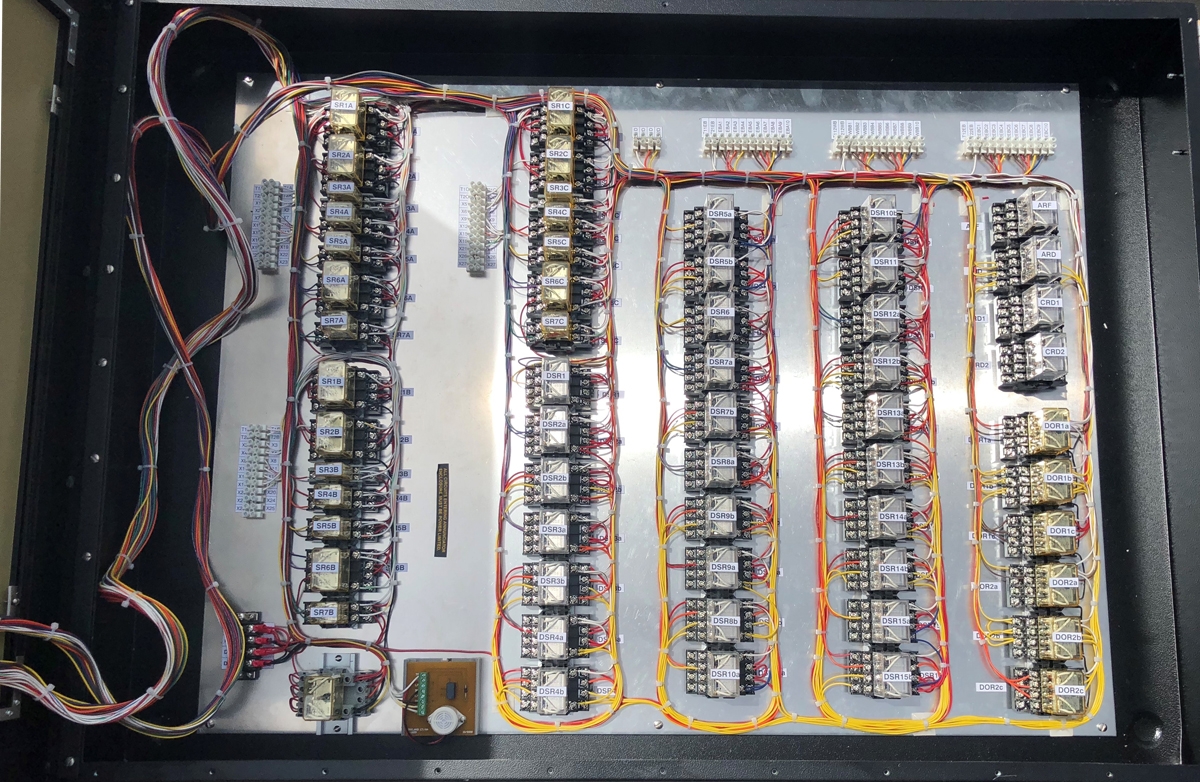

We’re Wired!

Kirkland has solutions for unique situations regarding interface with building automation systems. We can utilize a number of options as we did here with relays to assist the communication between our panels and the building’s system. This Smoke Control Panel / Door Override Panel combo uses relays to work around the client’s wiring limitations.